32 Harley Crescent Condell Park NSW, 2200 Australia

Laser Cutting Service Tips to Keep Ahead of the Game

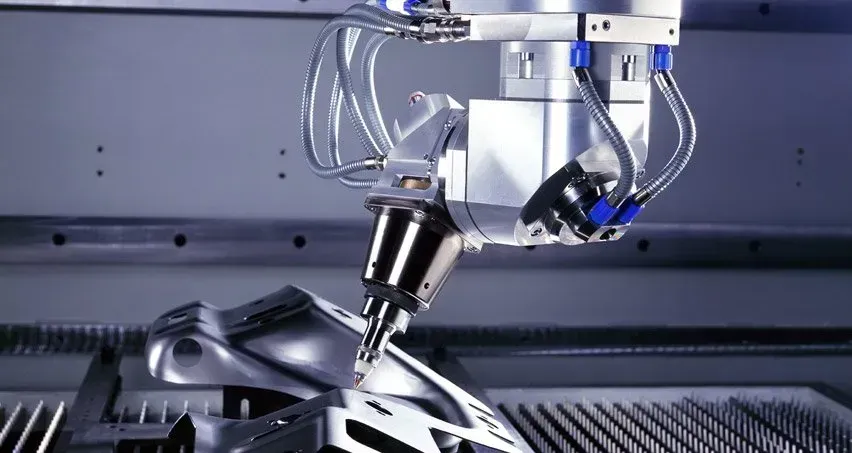

In light of today’s economy, fabricators are forced to change their business models unlike ever before. There has to be a strong marriage between change and innovation to remain competitive. The difficulty when it comes to laser cutting

service in NSW is understanding how those changes and new technologies are going to impact the entire process chain.

Latest Innovations in Laser Cutting Service in NSW

Some of the most recent technologies to hit the market include fiber lasers that are working with 4-kW power to cut material that is thicker and doing it at a much faster rate than prior machines. Automated setups are making the process faster and reducing the errors in laser cutting services. While these technologies are taking over shop floors in many fabrication shops, one problem arises; the added demand on other areas of the process chain.

Setting the Pace

This leaves many fabricators wondering how best to approach these new bottlenecks in the process chain. The very first thing that needs to be addressed is defining the process. For many businesses, this is not happening. It requires the company to take a comprehensive and whole view of the operations to outline what the process chain should look like. This will involve everything that occurs in the shop from the moment the order is taken to delivering it to the customer.

These new innovations that are hitting shop floors are often viewed as panaceas to production problems. However, it is vital to assess whether these new machines are producing more parts for delivery, creating more capacity, and where that increase in capacity is in the process. Laser cutting services in Australia need to realise that with more capacity or higher production comes bottlenecks in other areas and determines how to reduce costs and time constraints in all areas of the process, not just the actual cutting process. There are many ways to keep up and make changes all the way through the process chain. Maybe software for order management is the right answer or automated setups if the hold-up is at the operator level. Whatever the issue is, changing and keeping up with current technologies is key for fabricators to stay on top of the industry and move into the future.

Get in touch

for more information.

RECENT POSTS