32 Harley Crescent Condell Park NSW, 2200 Australia

How Laser Cutting Benefits the Automotive Industry

Laser cutting is an innovative technology that has been increasingly used in the automotive industry for years. In the past, mechanical cutting was the only way to cut vehicle parts. But today, laser-cutting machines are taking over for good reason. Just like all manufacturing aspects, every automobile component demands the utmost reliability throughout the production process.

Automotive manufacturers are responsible for ensuring that every vehicle put out on the market is safe for public use. This is why laser cutting is so beneficial as it offers unbeatable precision. However, the benefits of Sydney laser cutting don't stop here. In this blog, we will delve deeper into the advantages of laser cutting and how it is revolutionising the automotive industry. Continue reading to know more.

Can laser cut steel and what is the maximum thickness it can handle?

Most laser cutters can handle materials with a thickness ranging from 0.5 to 12 mm, depending on the type of material being cut. However, when using fibre lasers for laser cutting metals, the usual upper limit for cutting thickness ranges from 20-25mm for mild steel. Beyond this, higher power CO2 lasers are employed.

What type of laser cutter is used to cut steel?

CO2 lasers and fibre lasers are two of the most commonly used lasers in the automotive industry. However, most of these steel materials often possess considerable thickness, which basically requires high-power cutting tools. In such cases, CO2 lasers are the preferred choice due to their ability to generate higher power cuts compared to other types of lasers.

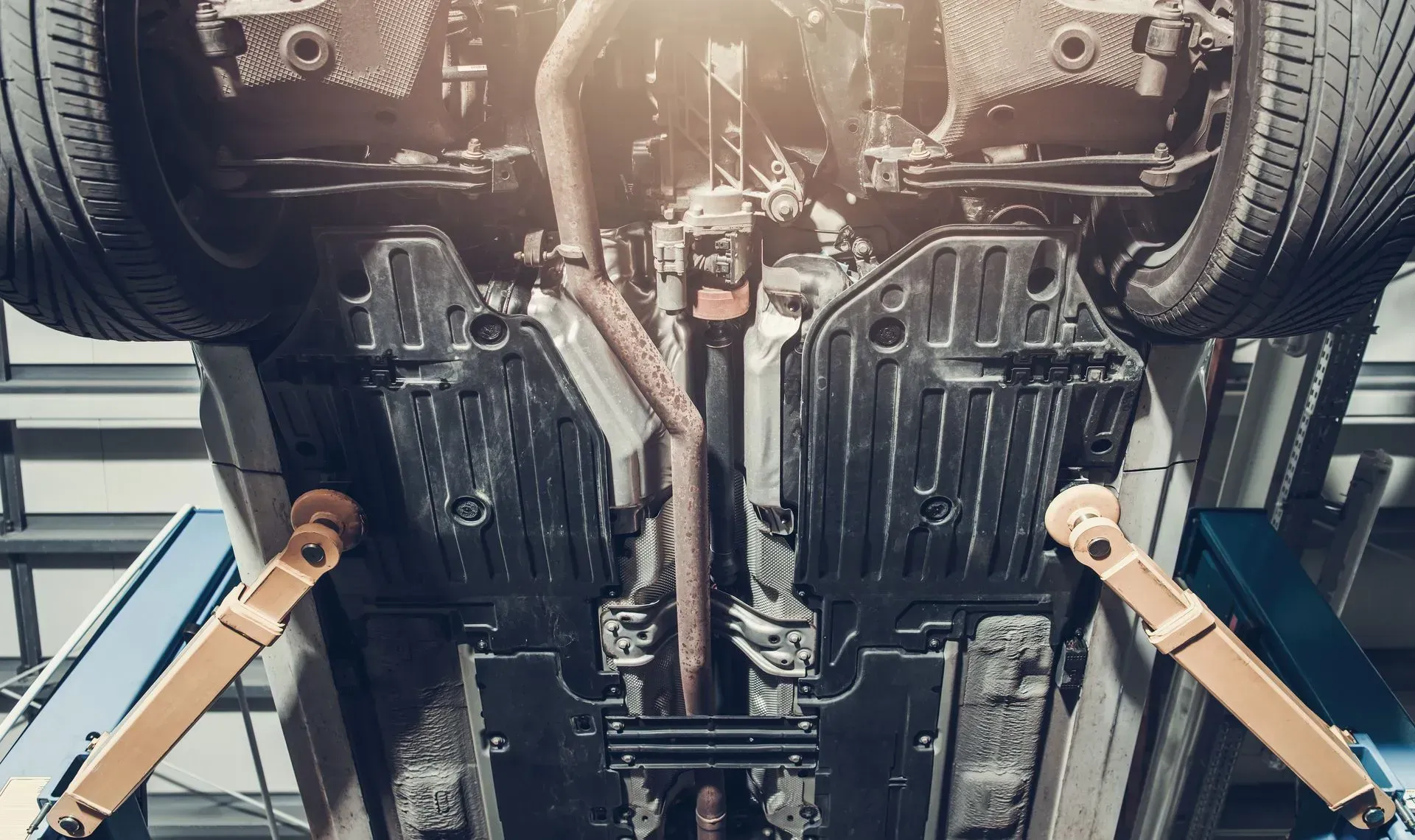

How is laser cutting used in the automotive industry?

Over the years, laser cutting has revolutionised the automotive industry with its ability to provide highly precise and intricate cuts to automotive parts. From cutting plastics and fabricating metal parts to marking and engraving, laser cutters are widely used in a variety of automotive applications due to their remarkable efficiency. By integrating laser cutting with robotic systems, the manufacturing process of high-quality parts can be optimised, leading to enhanced efficiency and cost-effectiveness within the automotive industry.

What are the benefits of laser cutting in the automotive industry?

Laser cutting in the automotive industry comes with a multitude of benefits that contribute to its growing popularity. Here is a list of some of its most important advantages:

Clean and Precise

When it comes to the manufacture of automotive parts, it often demands exact measurements and a high level of precision to ensure proper functionality and safety. This is where the application of laser-cutting technology comes into play. Its extreme accuracy is capable of achieving up to

+/-0.1mm precision, which surpasses the capabilities of many traditional cutting methods.

The laser beam can create complex shapes with very tight tolerances, making it perfect for producing high-quality automotive parts. Moreover, laser cutting produces clean edges with no burrs or inconsistencies, which helps to reduce post-processing time.

Laser cutters are ideally suited for cutting and sealing airbags. Having a virtually error-free method for sealing airbag covers, laser systems have become the leading technology in this application. The laser cutter's key advantage lies in its strong and precise heat, which ensures effective airbag sealing.

Versatile

In the automotive sector, lasers are successfully used to process a wide range of materials such as plastics, fabrics, glass, rubber, metals, and other materials. Since their cutting heads are CNC controlled, laser systems can move precisely to cut the programmed outlines in the laser cutting machine.

No matter how hard the type of material is, the laser cutting process remains unaffected, allowing it to cut various materials, including steel, stainless steel, aluminum alloys, galvanised steel, and more. This technology provides an advantage for the automotive sector as it significantly reduces production time by ensuring parts are cut precisely every time.

Car components and materials that have undergone laser processing can be found in both the exterior and interior of standard vehicles. From the initial design and development up to the final assembly, lasers play a crucial role in the entire production process of automobiles today.

Innovative

When dealing with automotive materials, one of the main challenges is preserving their structure. Traditional shaping methods involve pressing and touching, which can weaken the material. However, laser cutters offer a solution by moulding the materials through a non-contact process.

What laser does is it cleanly melts the fibres so the material maintains its integrity, allowing it to achieve the desired outcome. Through this technique, material engineers can develop innovative mixes of metal and fibre materials that were previously just beyond imagination.

Extremely Compact

Laser cutters are extremely compact and they are widely known for their precision when it comes to manufacturing automotive parts. In fact, the use of laser cutting machines has become vital for vehicle manufacturers due to their high output-to-space efficiency.

Having an extremely compact characteristic, laser cutting machines enable seamless integration of manufacturing lines. These laser systems occupy minimal space, freeing up valuable floor area for other equipment. What's more, the small size of laser-cutting machines also makes them suitable for use in smaller automotive shops without compromising precision and accuracy when producing high-quality parts.

High-Quality

When it comes to quality, laser cuts are top-of-the-line. Having a steady beam of light that can cut through various materials with exceptional accuracy and precision, laser cutters can produce parts and components that meet strict automotive industry standards. On top of that, these high-quality cuts are produced at a quicker processing time than with other cutting methods.

Laser systems are excellently suited to enhance the production of automotive parts at every stage of the car manufacturing process, from the initial design phase and part development up to final assembly. However, they aren't just limited to large-scale production as laser systems are also used in manufacturing high-end custom cars, where the production throughput is lower, and certain tasks remain manual.

As a result, rejection rates are minimised, and the wastage of expensive materials is reduced, making them ideal for both small-scale and large-batch productions.

Cost-Effective

Comparatively, laser marking/engraving proves to be a more cost-effective option than other alternatives, primarily because it avoids the substantial consumable expenses associated with inkjet printing technology. Laser cutting typically produces marks that are highly durable and resistant to fading, making them more long-lasting and indelible in most scenarios.

Hot stamping offers excellent durability and produces high-quality marks, but it comes with reduced flexibility since each mark requires a different die. With laser marking, you can be provided with a swift, flexible, and adaptable solution in a single operation. No need to change tools or deal with downtime because the marking details are modifiable.

Sustainable

According to an environmental projection report, the estimated accumulation of scrap metal could reach a staggering 1 billion metric tons by the year 2027. This accounts for over 50% of the new car material in modern vehicles comprising recycled steel and aluminum.

While this may seem like an advantage, improper cutting of these materials can lead to increased waste and additional costs for manufacturers. Through laser cutting technology, automotive manufacturers can optimise cutting patterns, making the most efficient use of materials and significantly reducing scrap waste.

Takeaway

Laser cutting has earned a reputation in the automotive industry over the years, by delivering success in its precise and high-quality cuts. It has not only advanced various cutting applications but it also revolutionised the automotive manufacturing process.

Using the laser system, automotive manufacturers can produce high-quality products at a faster pace. Not only that, but the technology allows for precise parts with intricate detailing while minimising material waste.

Indeed, the advantages of laser cutting have helped the entire automotive industry in saving costs, producing higher-quality products and significantly reducing scrap waste. At Hygrade Laser, we provide reliable laser cutting services to help automotive manufacturers create parts efficiently. Contact us today for more information on how our laser-cutting services can revolutionise your automotive business.