32 Harley Crescent Condell Park NSW, 2200 Australia

Can You Cut Mylar With a Laser?

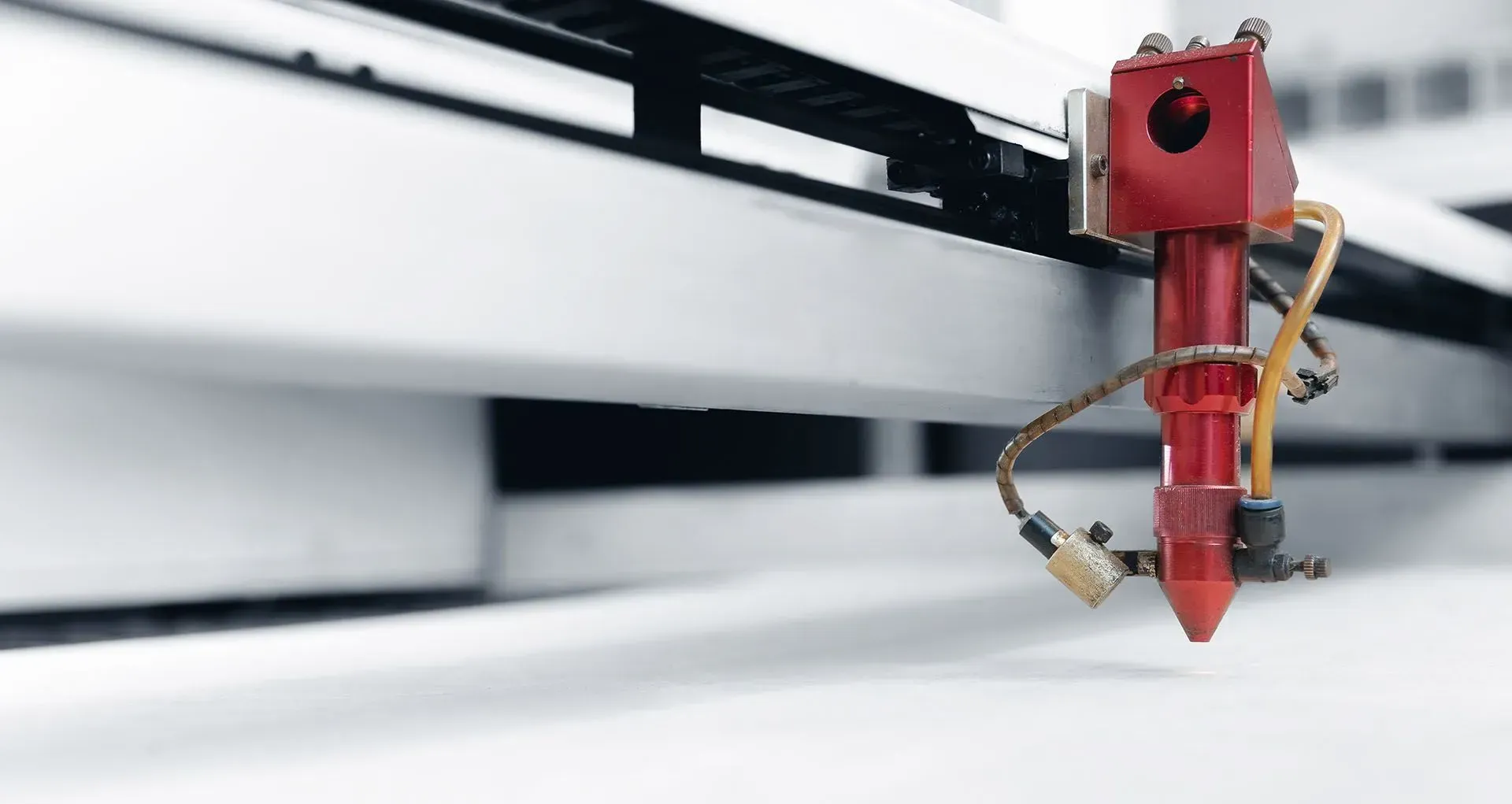

We all know that laser cutting machines are used in various applications. From cutting metal sheets to crafting intricate pieces, laser cutting has become an essential tool for many industries. But have you ever wondered if it's possible to cut Mylar with a laser? In this blog, we will explore this topic and provide you with all the necessary information regarding the best settings to apply when laser cutting Mylars.

In the following sections, we will also explore a step-by-step process that professional laser cutting services in Sydney follow when cutting Mylar stencils. Furthermore, we will provide you with valuable tips on how to achieve the best results for your stencils. But before we get into the details, let's first understand what Mylar is and its various applications.

What is Mylar?

Mylar is a type of plastic film that is made out of polyester resin. This thin sheet of plastic is widely used in various applications because of its excellent dimensional stability, durability, impermeability, reflectivity, transparency, and high tensile strength. Given these properties, it is ideally used in laser cutting applications. Laser cutting Mylar is a relatively simple process, as the material melts easily when enough heat is applied.

Since the material is thin, transparent, flexible, and resistant to moisture, chemicals, and punctures, mylar sheets are frequently used as a protective barrier in packaging to safeguard items such as food, pharmaceuticals, and perishable products from the harmful effects of moisture, gases, and contaminants.

The durability, strength, and versatility of mylar sheets also make it a popular choice for artists, designers, and photographers which they use to laser cut stencils, draft film, and overlays. Furthermore, Mylar is also commonly used in electrical and electronic applications, particularly on printed circuit boards, to prevent short-circuiting and other electrical malfunctions.

Which applications can you use Mylar?

Mylar sheets are used in a wide variety of applications ranging from packaging, printing, electronics, and other industrial applications. But, if we're talking about some of its most common uses, Mylar is often used to create stencils for intricate patterns and designs on fabric, walls, furniture, and other surfaces. Mylar is commonly known in the screen printing industry and is often used to print logos, designs, and text on t-shirts and other garments.

What can you use to cut Mylar?

Laser cutters are the most commonly used tools when it comes to cutting mylar sheets due to their ability to produce precise and intricate shapes.

CO2 laser cutter, in particular, is the most preferred choice as it can cut through thin layers of Mylar easily without damaging the edges. During the process, the laser beam is directed onto the mylar sheet, melting and vaporising it to create a clean cut. Thus, no further finishing work is required.

But aside from this, laser cutters are also a popular choice due to several advantages:

Precision

A laser cutter offers a high level of precision, which is essential when laser cutting stencils, templates, or intricate designs. The laser beam used to cut the mylar stencil has a very small diameter, ensuring that the shapes and curves are accurately rendered.

Clean

Laser cutting produces clean and sharp edges in Mylar stencils without fraying or melting, which can occur with other traditional cutting methods.

Non-Contact

Laser cutting is a non-contact process, which means that there is no direct contact between the cutting tool and the material. This characteristic is beneficial for fragile materials such as Mylar, as it reduces the potential for damage.

Automation

A laser cutter can easily be programmed to laser cut stencils and other specific designs that require precise measurements and shapes. Automation helps to increase efficiency, accuracy, and repeatability while cutting Mylars. Thus, making them suitable for both single and mass production of Mylar components.

Minimal Material Waste

Laser cutting is an efficient method that is known for minimising material waste, which is particularly beneficial when working with more expensive materials like Mylar.

How to laser cut stencils with Mylar?

Here is a step-by-step process on how to laser cut stencil that is made out of Mylar.

- The first step is to convert your preferred pattern or design to a vector format. Vector formats contain precise lines and curves which are easy to trace and cut with a laser cutter. So whenever possible, opt for designs that can be easily converted into a vector format such as an SVG file.

- Choose the appropriate thickness of your Mylar sheet based on the requirements of the stencil design. You may also need to adjust it according to the power capacity of the laser cutter. The thicker the sheets are, the more power the laser needs to cut through it.

- Fasten the Mylar sheet securely to the cutting bed of the machine, ensuring it lies completely flat. A solder paste will then be applied over the sheet , after which a laser beam will melt and vaporize the paste to cut the design out. You don't want any ripples or bumps as this could cause your stencil to be cut inaccurately. Once the process is done, your laser cut stencil is now ready for use.

What is the recommended thickness to laser cut stencils?

A thin sheet of Mylar only requires a thickness of 0.1 mm to 0.2 mm to produce a good laser cut stencil. While it is possible to laser cut Mylar with various thicknesses, it is not recommended to use thick Mylar sheets when creating stencils as it can be difficult to ensure a precise cut.

What is the ideal laser cutting speed when cutting Mylar?

The best speed when laser cutting stencils depends on how thick your Mylar sheet is. If you are working on thick materials measuring 0.203 mm to 0.36 mm, you need to adjust the laser settings and apply a slow cutting speed and a high laser power to achieve consistent results. For this, you should apply a cutting speed of 30 mm/s and a power rating of 10W to prevent the material from getting burrs and uneven edges which are not ideal for laser cut stencil designs.

What power level is recommended for high-quality laser cut Mylar?

In general, most Mylar parts with a thickness of 4 mils (0.1 mm) would only require a power level of 6W and a cutting speed of 150 mm/s. However, if you are working with a thicker material, a higher power level of 10W and a lower cutting speed of 30 mm/s is recommended for better results. Since laser cutters have a high precision, most laser cut parts won't need finishing.

What are the best settings for laser cutting with Mylar?

The settings vary based on the specific machine and the thickness of the Mylar sheet to be cut. The following settings provided on this list are only recommended. Hence, it is recommended to test and adjust settings for your specific laser cutter to achieve the desired results.

Here is a list of the standard settings suitable for cutting a 4-mil thick Mylar sheet with a laser cutter.

Power

When cutting a 0.1 mm Mylar, you need a 25W laser power to achieve good results.

Speed

To avoid melting the edges of the material, it is recommended to use a machine speed of 250 mm/s to prevent excessive heat exposure to a single point by the laser.

Passes

Thin sheets of Mylar only require a single pass.

Focus Height

While you can manually adjust the focus height, it's recommended to use the autofocusing feature to get the best results.

Can a diode laser cut Mylar?

While not all laser cutting machines can cut Mylar effectively, the suitability of a laser cutter depends on factors such as the power level and calibration of the laser.

In general, a diode laser can cut Mylar but it might not be as efficient or precise as a CO2 laser. Diode lasers are typically used for lower-powered applications and may require multiple passes to cut through Mylar. CO2 lasers, on the other hand, are more commonly preferred for laser cutting stencils due to their precision and ability to make cleaner cuts in a single pass.

Is Mylar easy to cut?

Mylar is generally easy to cut if you will use the right laser cutter. Due to its low vaporisation temperature and small thickness, you can easily cut it using low-power lasers. However, depending on the thickness of the Mylar and the complexity of the stencil design, a CO2 laser can make clean cuts with minimal time and effort.

But if you need to produce intricate shapes or deep cuts, a CO2 laser is the preferred option. However, it's important to note that when producing laser cut stencils, it's essential to select the right laser settings according to your machine's specifications. Otherwise, you may end up with either poor quality cuts or damage to your material.

Takeaway

Cutting Mylar with a laser is certainly possible, and can be an effective method for creating precise laser cut stencils. Mylar which is one of the materials used in stencil making, can be accurately cut by lasers without causing any damage. However, when using these machines, it's important to select the right laser settings based on your machine specifications to achieve the best results possible. By knowing the right settings in terms of power, speed, passes and focus height, you can ensure that your laser cutter is providing reliable and consistent cuts.

At Hygrade Laser Profiling, we offer the best laser cutting services in Sydney. Our laser cutting specialists use state-of-the-art equipment to offer the best-tailored solutions to our clients. While our services do not include cutting of plastics, we can customise products for various industries ranging from street furniture, food, mining, boating and motorsport industries, architectural pieces, and even signage. For more information about what Hygrade Laser Profiling has to offer, get in touch with us today.