32 Harley Crescent Condell Park NSW, 2200 Australia

15 Different Types of Metal, Their Properties and Uses

Looking for a professional laser cutting company in Sydney? Hygrade Laser Profiling has been providing advanced laser cutting services for over 30 years.

All types of metal have distinct qualities, but some are more suitable to particular uses than others depending on their melting point, density, and malleability. The three most popular types of metal and alloys used in industrial works will be described in detail below, along with their uses and applications.

The Classification of Metals

Iron content

The most common method in classifying metals is based on iron content. The three categories are: ferrous metal, nonferrous metal, and alloys.

- Ferrous (contains iron)

Metals that contain iron are referred to as ferrous metals. Since they are renowned for their tensile strength, these metals are used as a structural building material to make bridges, trains, and other projects that involve construction and architecture.

Generally, iron has a propensity for corrosion, particularly when it is exposed to moisture. This makes ferrous metals susceptible to rusting, especially when used outside.

- Nonferrous (contains no iron)

Non-ferrous metals generally have no iron content and do not display any corrosive and magnetic properties. And although they can be used in a variety of applications, extracting them may be more arduous and costly. Some of the non-ferrous metals include Aluminium, Copper, Lead, Magnesium, Zinc, and Brass.

- Alloys (contains multiple metals and other elements)

Unlike ferrous metal and nonferrous metal that are classified by having an iron content in them, an alloy is created using a combination of metal either with another metal or a nonmetal part.

Metal alloys are created by melting, mixing and cooling them in room temperature until they become a stable form.

Atomic Structure

Based on the Periodic Table, metals can also be classified according to their atomic structure. Metals can either be classified as Alkaline, transition metal, or alkaline earth. When reacting with other elements, metals from the same family often behave similarly. Thus, they have comparable chemical characteristics.

Alloys are often preferred by metalworkers due to their versatile nature and longevity compared with pure metals. That is why it's not uncommon to find various alloys being used in the metalworking industry, as pure metals are rarely used.

Some of the most used alloys include mild steel alloys, cast iron alloys, stainless alloy steel, and aluminium alloy steel.

List of the Different Types of Metals

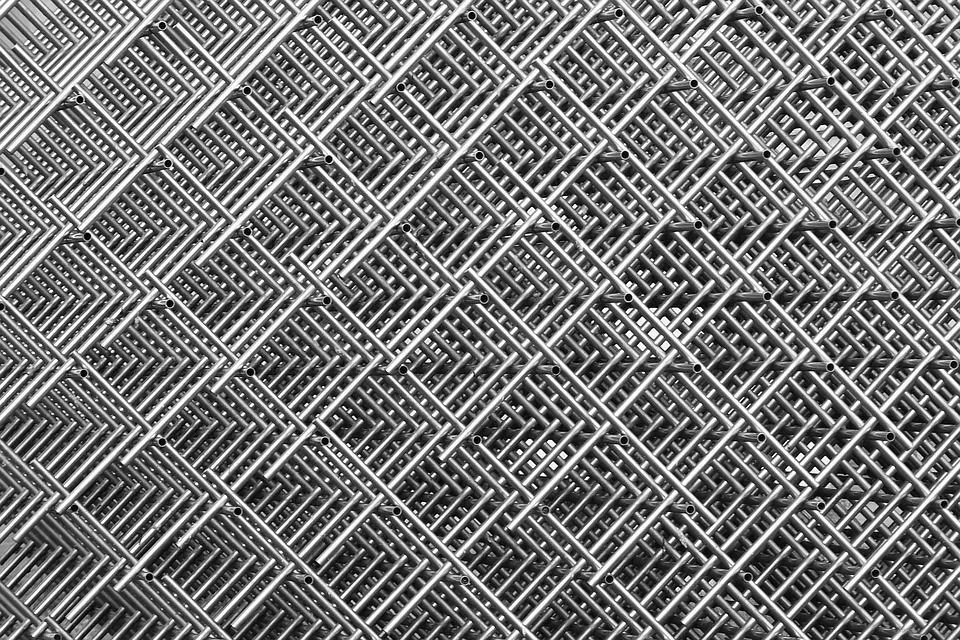

Steel

Having the characteristic of being stronger than other metals, pure iron is still not corrosion resistant. Thus, steel was created by incorporating carbon into iron to somewhat address these limitation.

Apparently, steel can be classified into four main types - carbon steel, alloy steel, tool steel, and stainless steel.

1. Carbon steel

Carbon steel, which is made from the mixture of carbon and iron, is more durable than iron itself, which is why steel is frequently used as a building material.

Steel can be divided into three groups based on its iron content: low carbon steels, medium carbon steels, and high carbon steels.

Low carbon steel - carbon content in low carbon steel ranges between 0.1% and 0.3%. It is commonly ductile than iron, but harder and tougher. It is commonly used to make scaffolding, vehicle bodies, storage containers, oil drums, screws, nuts & bolts, and nails.

Medium carbon steel - carbon content in medium carbon steel ranges from 0.3% to 0.7%. It is strong and has a high tensile strength but tougher and less ductile than mild steel. It is commonly used in the production of products that must be durable and hard-wearing, such as gears, tools and keys.

High carbon steel - carbon content in high carbon steel ranges from 0.7% to 1.3%. Since its raw material is extremely brittle and hard, it is used for cutting tools and durable products such as guillotine blades and springs.

2. Alloy Steel

Cast iron belongs to the iron-carbon alloy steels that has a carbon content of more than 2%.

Due to its good tensile strength and flexibility, malleable cast iron is a popular choice for a variety of applications that include electrical fittings and equipment, hand tools, pipe fittings, washers, brackets, farm equipment, mining hardware and machine parts.

3. Tool steel

Tool steel refers to any carbon steel that is perfectly suited to produce tools such as cutting tools, dies, hand tools, knives, and other items.

Due to their hardness, ability to resist wear and tear, and the capacity to maintain a cutting edge at high temperatures, they are suitable for shaping other materials through processes like cutting, machining, stamping, or forging.

Tool steel is typically used in its heated form. Numerous high-carbon tool steels have higher ratios of elements like vanadium and niobium, which make them more corrosion resistant.

4. Stainless Steel

Although stainless steel is technically an alloy steel type, it has many different varieties that it has already received its own category. Significantly, stainless steel has a high corrosion resistance compared with other types of metal due to the substantial amount of chromium present in it.

This means that rust is slowed by the ultra-thin barrier that the chromium forms as it corrodes. If you remove the barrier, another one will quickly grow in its place.

Since stainless steel is not prone to rust, it is commonly used in items that come into touch with food such as knives, tables, and utensils.

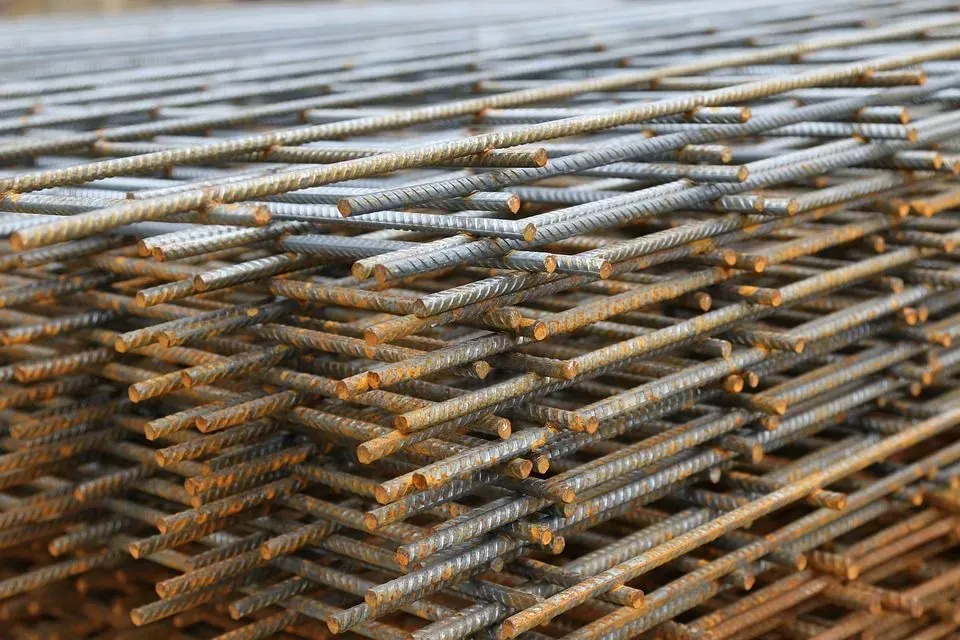

Iron

Unlike other metals that are difficult to find, Iron makes up around 5% of the Earth's crust. Pure metal, however, is not a stable element since it immediately combines with the oxygen in the air to form iron oxide.

Basically, a blast furnace is required to extract iron from its ores. Pig iron, which can be further refined to produce pure iron, will be produced by the blast furnace's initial stage. Iron is typically used for producing steel and alloys, resulting in approximately 90% of manufactured metals being comprised of ferrous metals.

1. Wrought Iron

Wrought iron is made up of pure iron and 1% to 2% of silicon, sulfur, phosphorus, and aluminium that are produced from smelting. Wrought iron is highly malleable as it is made by heating and then shaping chunks of iron.

2. Cast Iron

Cast iron, also known as gray iron, is typically used in high-quality cookware and contains trace amounts of silicon and manganese in addition to 2% to 4% carbon. Despite being robust, cast iron will break before it can flex or stretch.

Aluminium

Aluminium is a type of metal with the atomic number 13 and the chemical symbol Al. It has a specific gravity of 2.7 and a melting point of 658 degrees Celsius,

apperance

Aluminium is light and soft, often having a dull bluish-silvery hue. This dull look is due to the thin layer of oxidation that naturally forms when the metal comes into contact with air.

Density AND ELECTrical conductivity

Unlike most common metals, aluminium is less dense with a density of roughly one-third of steel. Moreover, aluminium has a high level of electrical conductivity, which is why it is essential in producing overhead cables, as well as aeroplane and car parts.

PROPERTIES AND USES

For most uses, aluminium would be too weak and squishy in its pure form, but when it is combined with trace amounts of other alloy metals, it becomes rigid and robust. Hence, it is capable of being blanked, molded, forged, and die casted.

Magnesium

Classified as an alkaline earth metal, Magnesium is a chemical element that goes solid at normal temperature. It has the atomic number 12 and the symbol Mg.

Appearance

In terms of appearance, magnesium is a silvery-white metal that burns brightly and ignites quickly in the air.

Density

In terms of density, magnesium is one-third less dense than aluminium. Adding magnesium as an alloying agent helps enhance the mechanical, fabrication and welding properties of aluminium. Hence, making it ideal for use in aeroplane and car construction.

Natural Abundance, properties, and uses

Despite being one of the most abundant elements in the Earth's crust, magnesium cannot be found in is pure form naturally. Rather, it is found in large concentrations of minerals such as magnesite and dolomite.

It can also be primarily found in the sea amounting to trillions of tonnes that most of the industry are using today. It can be produced by either reducing magnesium oxide with silicon or electrolysing molten magnesium chloride.

Magnesium is commonly used in items that require a lightweight material such as vehicle seats, luggage, laptops, cameras and power tools.

Copper

Classified as a transition metal, Copper is a chemical element that goes solid at normal temperature. It has the atomic number 29 and the symbol Cu.

Appearance

Copper is a reddish metal which has a face-centered cubic crystalline structure. Its structure causes it to reflect red and orange light, and absorb other frequencies in the visible spectrum, giving it its characteristic reddish colour.

Density and electrical conductivity

High purity copper has a density of 8.88 g/cm3. Not only is Copper malleable, ductile, and has an excellent electrical and thermal conductivity, but it also has great aesthetic appeal.

natural abunbdance, properties, and uses

Copper is abundantly present in the Earth's crust, as it is the 25th most abundant element at 0.01%, and has two naturally occurring isotopes, 63Cu and 65Cu with respective abundances of 68.94% and 31.06%.

Brass

Brass is typically created with a combination of copper and zinc. Depending on the ratio of copper to zinc, brass can be identified with a number of variations. By adding a minimal quantity of other elements, modifications can be made to the composition, providing differences in mechanical, electrical and chemical properties.

Appearance

Brass can appear reddish-gold, silvery-white, or dazzling gold at times. However, this might not always be the case. More zinc gives the alloy a silvery appearance, while more copper gives it a rose tone.

Density

Compared to bronze, brass is more ductile and has a similar level of low friction when in contact with other metals. Depending on the alloy, it has a low melting point of 900–1000 °C and a density of 8.73 g/cm3.

Properties and Uses

Compared to copper, brass exhibits greater durability but lower thermal and electrical conductivity. Brass products are known for their corrosion resistance and malleability. Thus, they are often shaped and moulded into locks, screws, valves, and gears.

Bronze

Classified under a copper alloy, Bronze is not a pure metal that occurs naturally. Hence, it cannot be find anywhere unless combined with two other metals.

Bronze is basically made up of copper and tin, although sometimes, it is combined with other elements such as tin and phosphorus or phosphorus and aluminium.

Bronze made from tin and phosphorus is highly flexible and gradually becomes harder. It is used to manufacture springs, sheets, pumps, and bearings. While aluminium-based bronze has an exceptional heat resistance that can be used to create coinage, ship parts, marine parts, and valves.

Appearance

In terms of appearance, bronze can initially be seen as reddish-brown and reddish-gold in colour, but as it oxidises, it becomes dark brown or green in hue.

Density and electrical conductivity

Bronze has a relative density of 8.8 g/cm3 and produces a little friction when in contact with other metals. Its melting point ranges from 950 to 1050 °C depending on the quantity of tin present. It also transmits heat and electricity efficiently having an electrical conductivity of 7.4 (10e^6 siemens/m).

properties and uses

Bronze is known to be stronger than copper, easier to mould than tin, and has a higher corrosion resistance than brass.

Aluminium-based Bronze is used to create a wide range of pipe fittings, pumps, gears, ships and turbine blades either by casting or forging.

Zinc

Classified as a transition metal, Zinc is a chemical element that goes solid at normal temperature. It has the atomic number 30 and the symbol Zn.

Appearance

Zinc can commonly appear as a bluish-white, glossy, diamagnetic metal. Though, it doesn't have any magnetic properties. Nonetheless, most of its commercial grades have a dull appearance.

Density

Zinc has a density of 7.140 g/mL, which indicates that it is relatively heavy and will float in water.

Properties and Uses

Zinc is initially brittle when kept at room temperature, however, it shifts to being malleable between 100 and 150 °C. It also has a reasonable capacity to conduct electrical connectors.

Furthermore, Zinc is often used in marine applications to provide cathodic protection against corrosion of other metals with its low electrochemical potential. Because of its extensive use, it can easily be melted and reused.

Titanium

Classified as a transition metal, Titanium is a chemical element that goes solid at normal temperature. It has the atomic number 22 and the symbol Ti.

Appearance

Titanium looks like a bright, silvery metal. It is sturdy, beautiful, and has a high corrosion resistance. While concentrated acids are soluble in pure titanium, water is not.

Density

Titanium's density is 4.5 grams per cm3 which is much less than iron, making its metal elements important in the aerospace industry.

Properties and Uses

Titanium is sturdy, lustrous, and resistant to corrosion. While concentrated acids are soluble in pure titanium, water is not.

Due to its resistance to heat and corrosion when coming into contact with carbon-fiber reinforced polymers, Titanium is being used for aircraft construction instead of aluminium parts.

Tungsten

Classified as a transition metal, Tungsten is a chemical element that goes solid at normal temperature. It has the atomic number 74 and the symbol W.

Appearance

Tungsten appears to be a bright and lustrous white-silver metal.

Density

Tungsten has a density of 19.3 Mg/m3 and a melting point of 3410°C that boils at 5930°C.

Properties and Uses

The filaments of old-style incandescent light bulbs frequently contained tungsten. However, since they use a lot of energy and emit a lot more heat than light, they have been phased out in many nations. Today, they are currently used as filaments in light bulbs and cathode ray tubes as well as electrodes, heating components, and field emitters.

Nickel

Classified as a transition metal, Nickel is a chemical element that goes solid at normal temperature. It has the atomic number 28 and the symbol Ni.

Appearance

When it comes to appearance, Nickel looks like a silvery-white metal found naturally in the Earth's crust.

Density

Nickel has a density of 8.902 g/cm3, which is extremely high as compared to water.

Properties and Uses

Other metals are coated with nickel to prevent corrosion. And since nickel serves as a catalyst for some chemical reactions, it is used to make coins, nickel-cadmium batteries, and nickel-metal hydride batteries, and is also used as a colorant to tint glasses green.

Cobalt

Classified as a transition metal, Cobalt is a chemical element that goes solid at normal temperature. It has the atomic number 27 and the symbol Co.

Appearance

Cobalt is a brittle, silver-white metal that belongs to group VIII of the periodic table and shares similar characteristics with iron and nickel. It is magnetically comparable to iron and has excellent magnetic properties in addition to having a glossy surface.

Density

Cobalt has a density of 8.9 g.cm-3 at 20°C.

Properties and Uses

Cobalt has a very high melting point and retains its magnetic properties at the highest temperatures of all magnetic elements. With this, it is used in many alloys to manufacture parts of gas turbine aircraft engines, high-speed steels, and cemented carbides.

Tin

Classified as a post-transition metal, Tin is a chemical element that goes solid at normal temperature. It has the atomic number 50 and the symbol Sn.

Appearance

In terms of appearance, Tin has a highly crystalline, silvery-white, soft, malleable, and ductile metal.

Density

Tin's density is 6.833 2.1222 g/mL with a 29% error.

Properties and Uses

Tin is a soft metal that is ductile and malleable, requiring only little effort to cut and fold. Thus, it can be easily rolled into a very thin sheet.

Tin is frequently employed in the production of tin foil for moisture-proof packaging, fine solder for important alloys, and protective coverings for iron and steel sheets.

Lead

Classified as a post-transition metal, Lead is a chemical element that goes solid at normal temperature. It has the atomic number 80 and the symbol Pb.

Appearance

Pure Lead is characterized by a cubic crystalline structure with a bright blue-white colour and a shiny luster. It does not have any other known allotropic modifications.

Density

The density of lead is around 11.34 g/cm3, which equates to a high density.

Properties and Uses

Lead is a corrosion-resistant metal that is quite malleable and is often used in piping and painting.

Lead was once employed to stop gasoline from knocking, but it was quickly realized that its byproducts caused major health hazards. Despite this, lead is still often used in creating ammunition, car batteries, radiation protection equipment, weights and sheathing of cables.

Silicon

Classified as a metalloid, Silicon is a chemical element that goes solid at normal temperature. It has the atomic number 14 and the symbol Si.

Appearance

Pure silicon, which shares many chemical and physical properties with diamond-like carbon, is a hard, dark grey, and glossy metal that has an octagonal crystalline form.

Density

Silicon's density is 2.33 0.563 g/mL with a 24% inaccuracy.

Properties and Uses

Silicon is often used in construction equipment, transistors, computer chips, solar cells, and waterproofing systems.

Takeaway

There you have , the most common types of metals, their properties, and applications. If you need a reliable laser cutting company that can customise and produce metal parts for your manufacturing requirements, look no further. Hygrade Laser Profiling provides complete manufacturing solutions from start to finish.

We laser cut some of the types of metals we've discussed in this article, such as steel, aluminium, brass, and copper. Our wide breadth of experience means that we have built up knowledge about how to solve laser cutting challenges and accomplish tasks with efficiency. Get in touch with us today!