32 Harley Crescent Condell Park NSW, 2200 Australia

Plasma Cutting vs Laser Cutting: Which Is the Right Technique for You?

If you need to laser cut materials for a particular project, Hygrade Laser has got your needs covered. As the leading laser cutting and manufacturing service provider in Sydney, we have everything you need to get the job done.

When it comes to cutting materials, there are a few different techniques that you can use. But in terms of popularity, people often talk about plasma cutting vs. laser cutting because they are two of the most effective methods. But which one is right for you?

Here’s a closer look at how these techniques work and what you should consider before choosing one over the other for your production needs.

What Is Plasma Cutting?

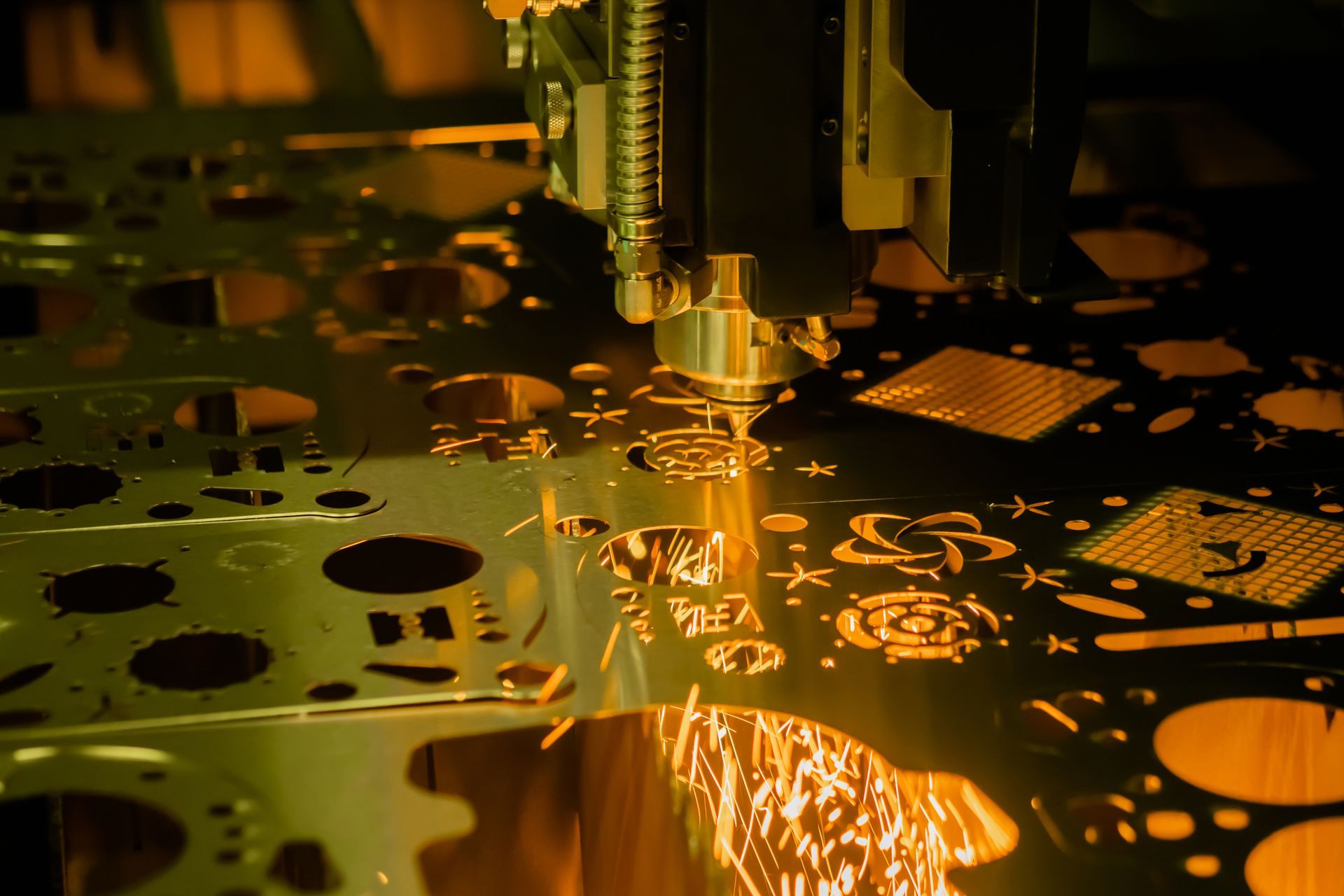

Plasma cutting, the oldest form of cutting, is a thermal cutting process that uses a plasma torch to cut through electrically conductive materials. Plasma is a gas that has been ionised by heat or electric current. The plasma cutting process is most often used when high-quality cuts are needed, either because the metal can’t be easily cut with a laser or because the design of the part makes it difficult to use other methods.

Plasma is an ionised gas that can be found naturally in the atmosphere and in lightning. People have been experimenting with plasma cutting since the 1950s when researchers discovered that they could control the process to produce a plasma jet that could cut metal. Today, most plasma cutters use compressed air to create the plasma.

Powerful magnets draw the plasma jet into a focal point where it contacts the metal and cuts it. The plasma jet cuts in a way similar to a laser, but with the advantage that it can cut thicker materials. Plasma cutters also produce a lot of flame and smoke during the cutting process, which may be undesirable in certain industries.

Plasma cutting is often used for materials like stainless steel, copper, aluminium, and titanium.

How Does Plasma Cutting Work?

A plasma cutting machine uses a high-voltage, high-frequency arc of electricity to create a plasma jet that cuts through metal. A plasma cutter is basically an air compressor attached to a small generator. The machine compresses air into a tank and pumps it through a nozzle. The nozzle creates an electric arc that generates plasma, which shoots out of the nozzle and hits the metal to be cut, melting it and creating molten droplets that fall away from the cut piece.

Plasma cutting produces a lot of smoke and soot during the cutting process. In fact, many people associate plasma cutting with its sooty smell since there are very few other processes that produce such thick smoke. The thick smoke makes it difficult to see what you are cutting, but it also acts as an abrasive on the metal being cut, helping to smooth out any imperfections in the surface of your project piece or part.

Because of this abrasive quality, however, you should never try to clean your workpiece if you use a plasma cutter. Instead, wait until after you have finished working on your project before cleaning any leftover soot off of your workpiece using water and soap (but not steel wool).

Plasma Cutting Advantages

- The main advantage of plasma cutting is that it can be used to cut thicker materials than laser cutting. One of the biggest advantages of plasma cutting over laser cutting is that it can be used to cut materials that can’t be cut with a laser. This includes materials that are too thick or are made from materials that aren’t conductive enough to be cut with a laser.

- Another advantage of plasma cutting is that it doesn’t create a lot of fumes like laser cutting does. This means that the process can be done indoors, even in areas where air quality is a concern.

Plasma Cutting Disadvantages

- The main disadvantage of plasma arc cutting is that it can be messy. The cut creates a lot of smoke and sparks. It also makes a loud noise as the plasma is being applied.

- Another disadvantage of plasma cutting is that it is slower than laser cutting. It can take up to ten times longer to make a cut with a plasma cutter than it does with a laser.

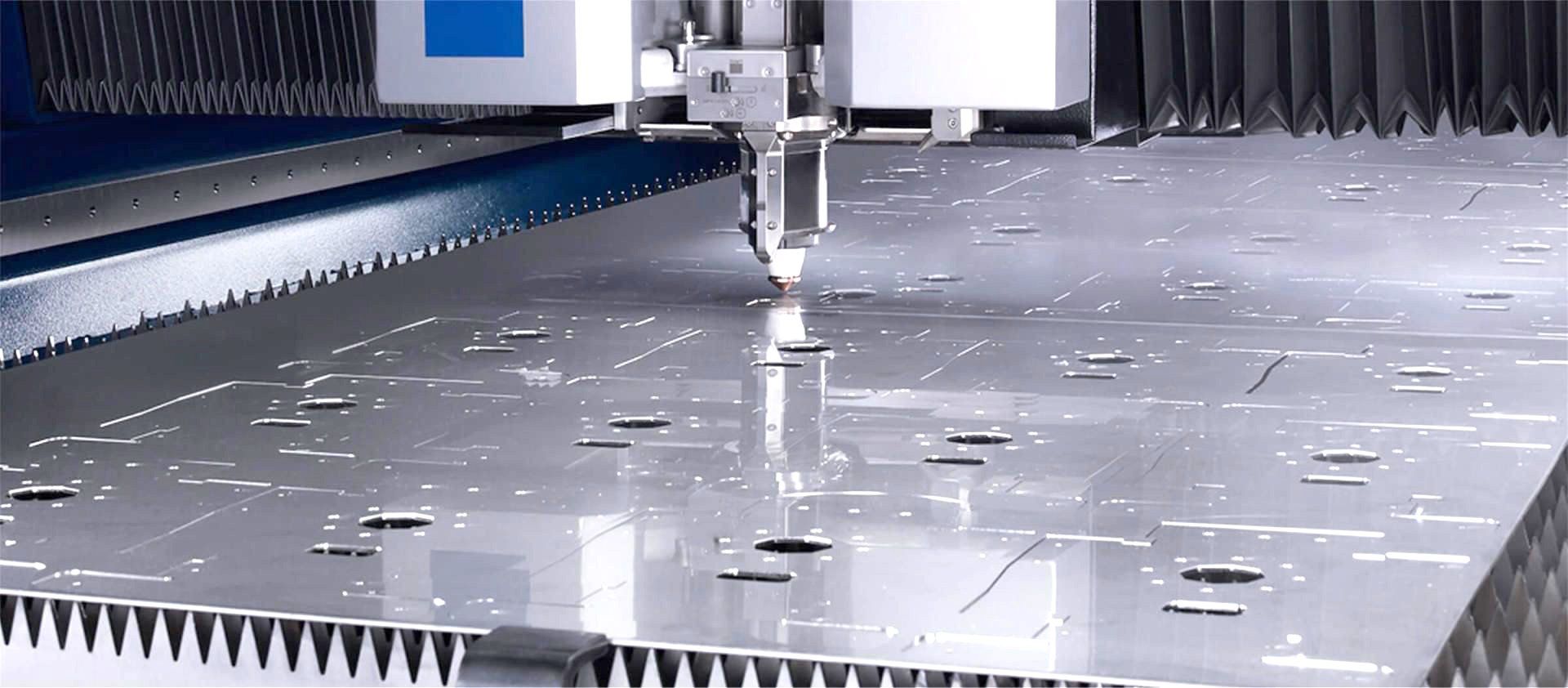

What Is Laser Cutting?

Laser cutting is a process for making parts using a laser beam to cut or etch metal or other materials. Like plasma cutting, laser cutting uses a stream of gas to make the cut. But a laser uses intense laser light instead of ionised gas to create a spark that excites the material. Laser cutting is used for parts that are too complicated or detailed for plasma cutters.

It’s suited for materials that aren’t conducive to plasma cutting, like stainless steel, nickel, and brass. Laser cutting is a common technique for making metal parts for aviation and space exploration. A laser beam is focused on material by way of a lens. This produces a small amount of heat on the surface of the material. The heat creates a reaction inside the material that creates enough pressure to force the cut.

How Does Laser Cutting Work?

The laser cutting process is used to cut or etch metal or other materials using a high-powered laser beam. The beam heats up the material in the path of the beam, which creates pressure from within that pushes outward against the surrounding material to form a cut line in it. The width of the cut line depends on how much energy was used to create it; higher energy levels produce wider lines than lower levels do because more heat creates more pressure pushing outward against surrounding material.

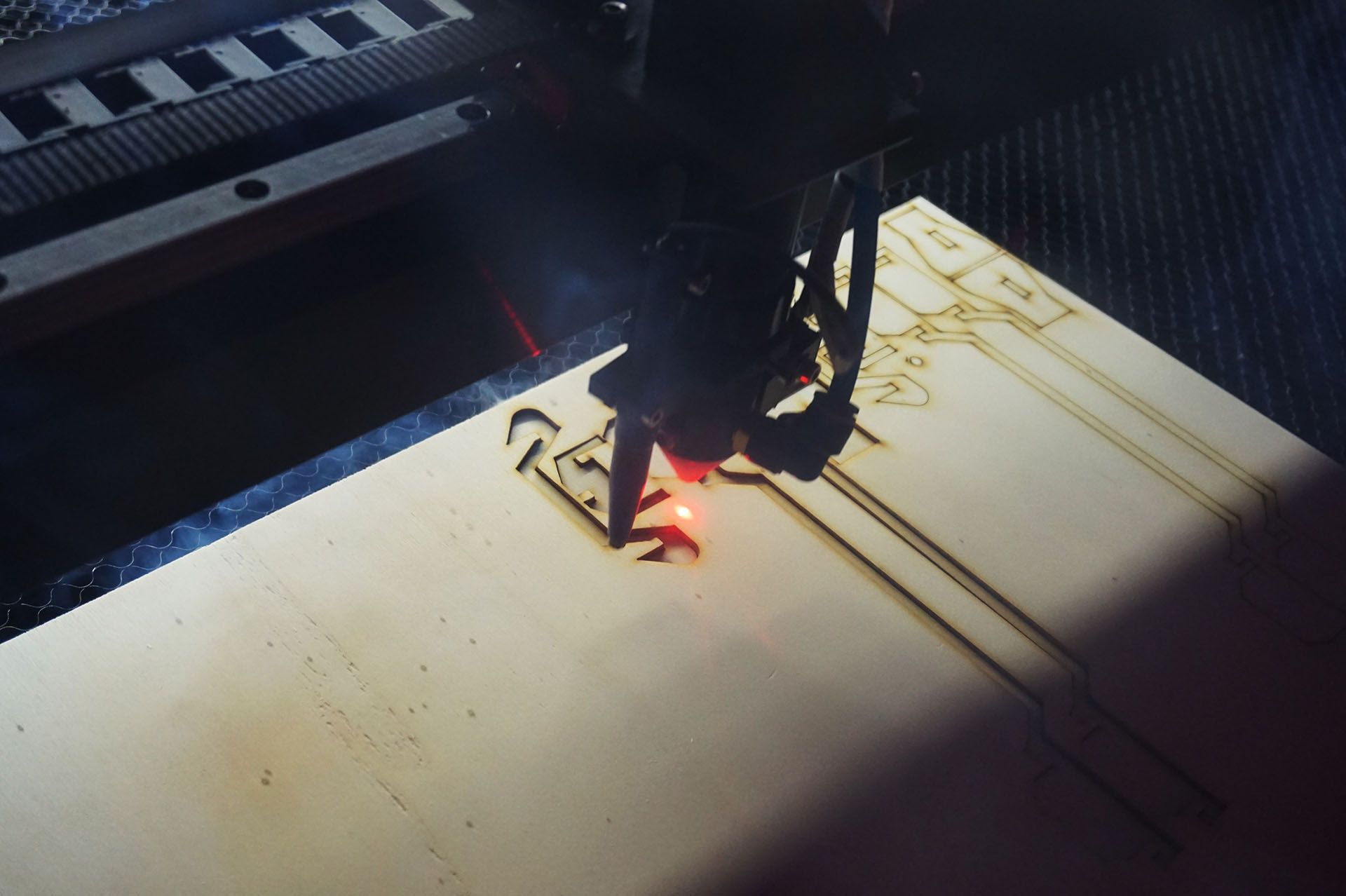

When cutting metal with a laser cutter, you can choose between two types: pulsed mode and continuous wave (CW) mode. The pulsed mode uses short bursts (pulses) of high-energy beams to cut through thick pieces while minimising warping or distortion in thinner pieces. Continuous wave mode uses one continuous beam at lower power levels for cutting thinner pieces. Laser cutting is a common manufacturing process for creating precision-cut parts for jewellery, electronics, and other industries.

Laser Cutting Advantages

- The main advantage of a laser cutter is that it can be used to cut intricate designs, like patterns or letters in words.

- Another big advantage of laser cutting is that it cuts very quickly and is great for large volumes of parts. This makes it an efficient process for high-volume production environments.

- Laser cutters can also be used to etch or otherwise modify the surface of the metal.

- Laser cutting is also safer than plasma cutting. This is because it creates fewer sparks and smoke. It’s also easier to control because the metal is being sliced, not burned.

Laser Cutting Disadvantages

- One disadvantage of laser cutting is that it is more expensive than plasma cutting. This is because laser cutters are more expensive and require more electricity than plasma cutters.

- Another disadvantage of laser cutting is that it can’t be used to cut thick materials. Parts must be less than 3/16" thick to be laser cut.

Plasma Cutting vs Laser Cutting: Which is Better?

When talking about plasma cutting vs laser cutting, the best cutting method for you will depend on what material you’re working with and the design of the part you need to cut. If you need to cut thick material quickly, plasma cutting is the better option. But if you need to cut intricate designs or don’t want to deal with messy smoke and sparks, laser cutting is the better choice.

Laser cutting and plasma cutting are both common methods for making metal parts. Each process has its own advantages and disadvantages that should be considered when deciding which one to use. Plasma cutters are faster but messier, while laser cutter machines are more expensive but cleaner and more precise. Ultimately, the best method for you will depend on your specific needs.

This depends on the circumstances. The most important thing to consider is what you are cutting. A laser cutter is good for intricate designs, while a plasma cutter is good for thicker materials. If you need both thick and thin sheet cutting, then you might want to use both laser cutting and plasma cutting.Engraving is the process of using a laser beam to remove material from the surface of a workpiece. Engraving can be used for both functional and decorative purposes. For example, engraving can be used to add text or images to a product, or it can be used to create patterns or textures on a surface.

Make Your Vision Real

Hygrade Laser Profiling is Sydney's leading laser cutting company. We have over 30 years of experience in working with a wide range of materials, from thin sheet metals to medium thick plate steels.

Our experienced and customer-focused staff are always ready to assist you with any aspect of your custom laser cutting project.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: