32 Harley Crescent Condell Park NSW, 2200 Australia

News

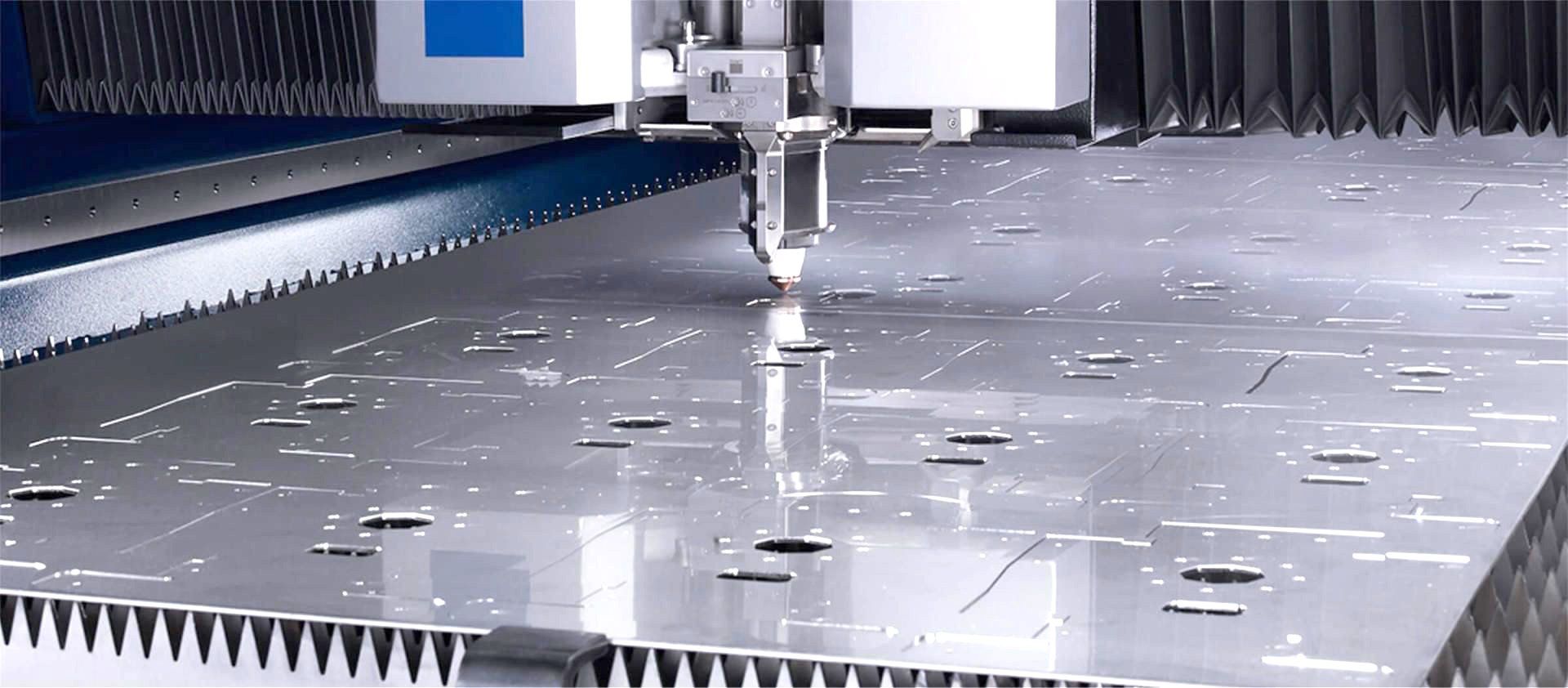

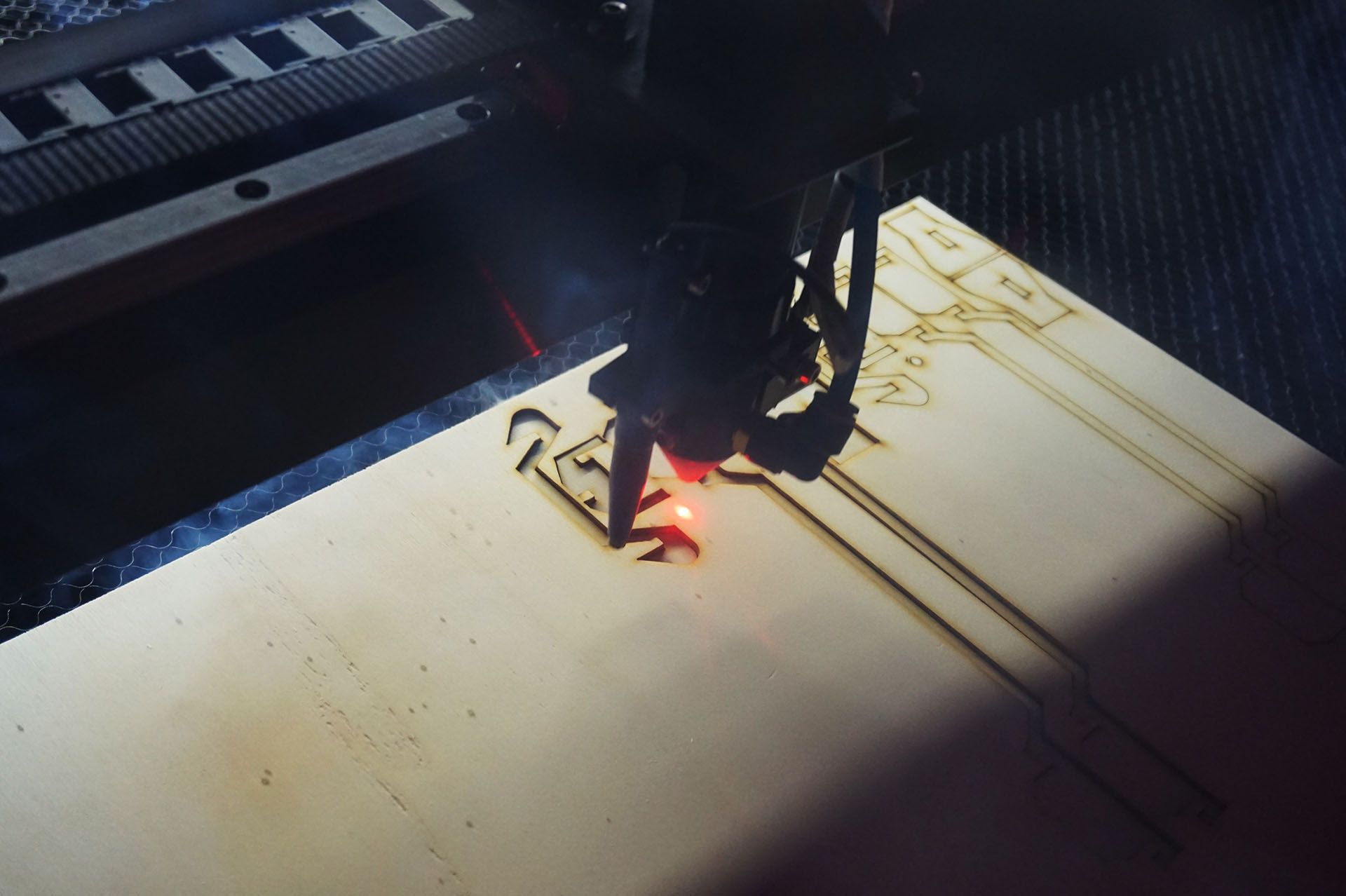

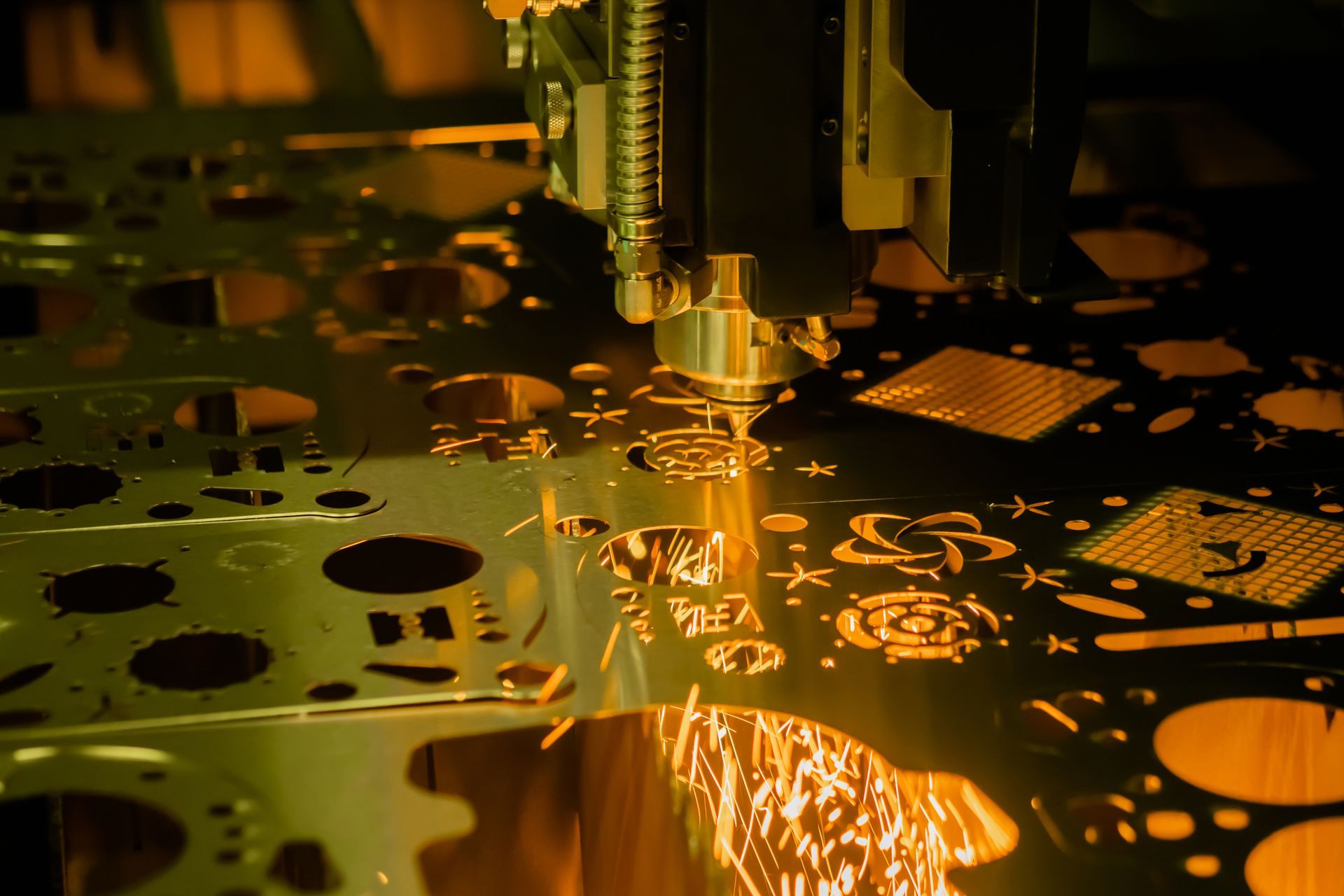

HYGRADE LASER PROFILING

NEWS

RECENT POSTS

Hygrade Laser Profiling has over 30 years professional experience in producing quality manufactured products through laser cutting, with great service that meets the needs of our local clients.

32 Harley Crescent Condell Park NSW, 2200 Australia

mail@hygradelaser.com.au

(02) 9791 1141

Find Us On: